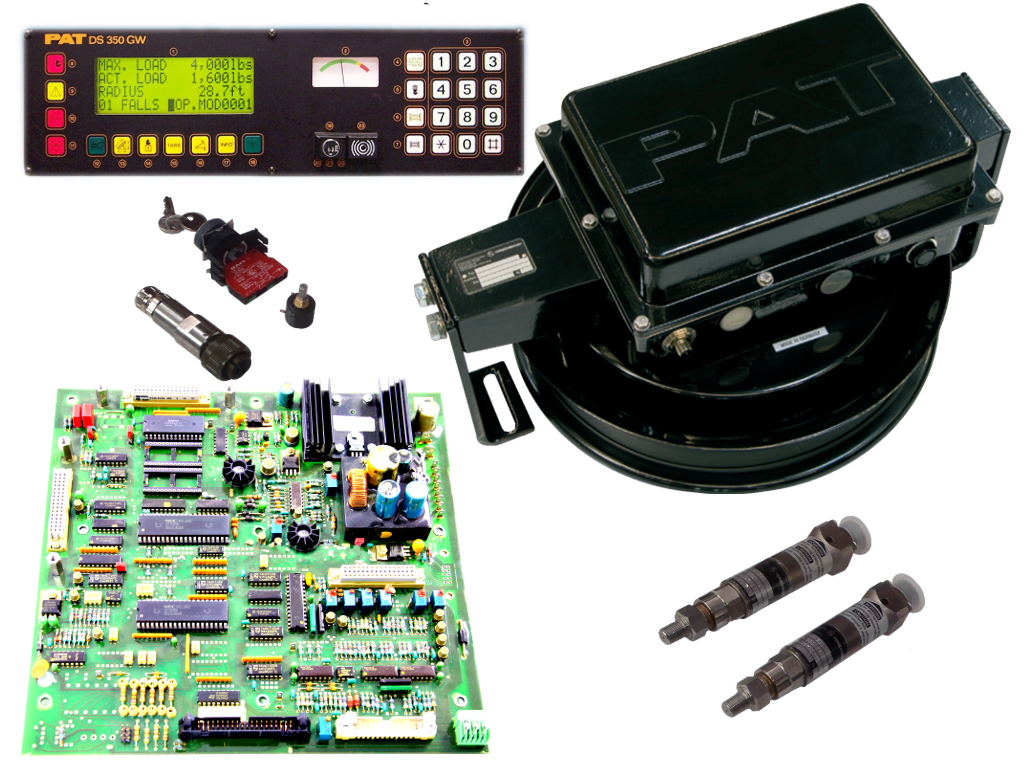

The BTS Parts Team specializes in the replacement of aging PAT Hirschmann Load Moment Indicator LMI systems including the PAT DS350G, PAT DS350 GW, PAT DS350 Vertical, PAT DS350 Interactive and other LMI and other systems on Grove, Link Belt, Manitowoc, National and other cranes.

With 35 years of industry experience, and thousands of customers, rest assured that our parts team can help. Contact us at 855.BODE.TEC toll free in the US or directly at 303.433.8878.

Full LMI Computer Replacement Options:

Individual Load Moment Indicator (LMI) Display Replacement Options:

Reach out to us directly and we will gladly give you the options you have for replacing your old PAT LMI load moment indicator

The Load Moment Indicator (LMI) complements the operator’s skill by providing the information needed to make the demanding lifts required of modem cranes and displaying it in the operator’s cab.

Using various sensing devices, the PAT LMI monitors all crane functions and provides the operator with a continuous reading of the crane’s rated capacity. The readings continuously change as the crane moves through the motions needed to make the lift. If hazardous conditions are approached, the LMI is designed to warn the operator by sounding an audible alarm and illuminating a warning light.

The LMI also provides the operator with information concerning certain geometrical data such as main boom length corresponding to the selected operating code, main boom angle, jib angle, jib length, operating mode and weight of the load on the hook, and the total weight being lifted by the crane.

Load Moment (or Rated Capacity) Indicator means a system which aids the equipment operator by sensing (directly or indirectly) the overturning moment on the equipment, i.e., load multiplied by radius. It compares this lifting condition to the equipment’s rated capacity, and indicates to the operator the percentage of capacity at which the equipment is working. Lights, bells, or buzzers may be incorporated as a warning of an approaching overload condition.

Load Moment (or Rated Capacity) Limiter means a system which aids the equipment operator by sensing (directly or indirectly) the overturning moment on the equipment, i.e., load multiplied by radius. It compares this lifting condition to the equipment’s rated capacity, and when the rated capacity is reached, it shuts off power to those equipment functions which can increase the severity of loading on the equipment, e.g., hoisting, telescoping out, or luffing out. Typically, those functions which decrease the severity of loading on the equipment remain operational, e.g., lowering, telescoping in, or luffing in.

Typical Load Moment Indicator Setup

More Load Moment Indicator, LMI System Information

The PAT Hirschmann Load Moment Indicator LMI system operates on the principle of reference/real comparison. The real value, resulting from the pressure measurement and geometric sensors, is compared with the reference data stored in the central processor memory and is evaluated in he microprocessor. An analog indication of % capacity is displayed via an operator’s console. When limits are reached, an overload warning signal is generated. At the same time, the crane movements that increase load moment such as hoist down, telescope out, and boom down will be locked out. The fixed data regarding the crane, such as dimensional data, capacity charts, boom weights, and centers of gravity are stored in memory chips in the central processor unit. This data is the reference information used to calculate the operating conditions. Boom length and boom angle are registered by the length/angle sensor, located inside the cable reel, mounted on the boom. The boom length is measured by the cable reel cable, which also serves as an electrical conductor for the anti-two- block switch. The crane load is measured by pressure transducers attached to the piston and rod side of the lift cylinder. Controls on the operator’s console allow the operator to select the operating mode (main boom, jib, etc.) as well as the parts of the line currently in use. The system will then limit operation to the capacities on the selected load chart, or the maximum permissible line pull in that configuration. After the engine is started and the PTO is engaged, the LMI powers up and conducts an automatic test of the complete system. After two successful system tests without errors, the system is ready for operation. In case of a system error, both the overload and anti-two-block lights on the central unit will illuminate. The interactive user guidance considerably simplifies the input of operating modes as well as the setting of geometry limit values.

Sample Load Moment Indicator LMI WARNINGS

- The LMI is an operational aid that warns a crane operator of approaching overload conditions and over hoist conditions that could cause damage to equipment and personnel.

- The device is not, and shall not, be a substitute for good operator judgment, experience and use of accepted safe crane operating procedures.

- The responsibility for the safe crane operation shall remain with the crane operator who shall ensure that all warnings and instructions supplied are fully understood and observed.

- Prior to operating the crane, the operator must carefully and thoroughly read and understand the information in this manual to ensure that he knows the operation and limitations of indicator and crane.

- Proper functioning depends upon proper daily inspection and observance of the operating instructions set forth in the operators manual