Project Description

The BTS Tech™ team of crane repair technicians take great pride in being some of the world’s most knowledgeable and effective crane repair technicians. With over 35 years of crane industry experience we provide expert crane repair, refurbishment, calibration, and parts services for the crane rental, rigging, construction, and refinery industries. Contact us toll free in the US at 855.BODE.TEC or internationally at +1.303.433.8878

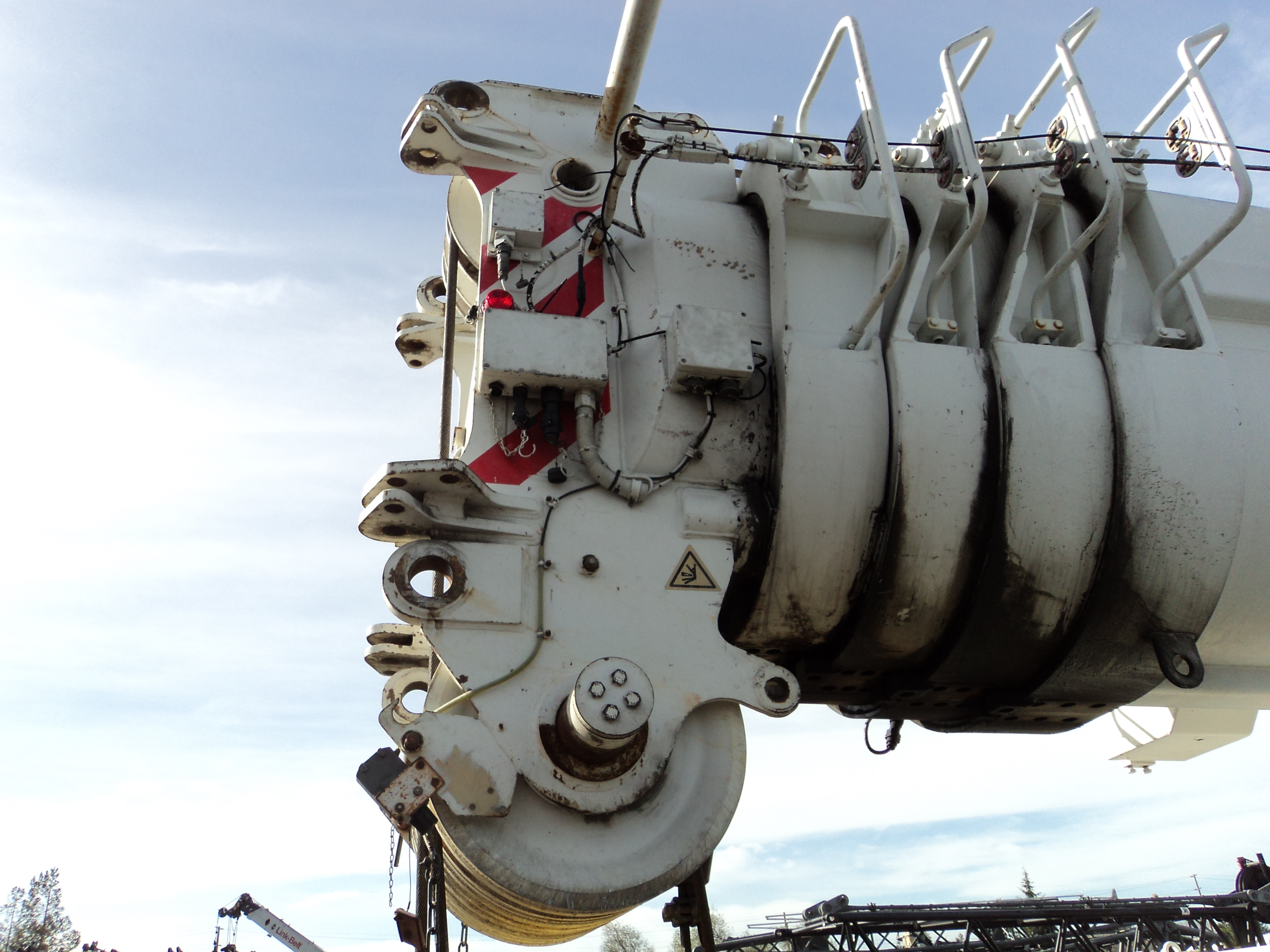

Recently we completed another crane repair service call on one of our customer’s Terex – Demag AC300 PAT Hirschmann PDC LMI in California. The crane repair service involved troubleshooting and repair of an intermittent failure of the PAT Hirschmann PDC system. This failure was particularly frustrating to our customer due to its intermittent nature and the unreliability that resulted from it when using the crane during a job. During the service and repair process, we identified some other issues in the crane electronics that were later addressed by the company mechanic with some guidance and instruction from BTS via phone.

- The customer reported intermittent loss of crane control; the PDC console screen indicated no error messages that identified the cause of the failure. The issue was noticed very infrequently initially however the frequency increased to a point of significant down time and frustration.

- Upon arrival we checked the reported issue and were able to quickly reproduce the intermittent failure.

- We checked the PDC service page and the analog input page of the PDC screen to verify the input signal from the sensors. The allowable range is 4mA to 20mA.

- On the Analog Input Screen Page, the boom-head angle sensor showed up as an unstable input reaching intermittently a value of 34mA that is clearly out of allowable range and causing the PDC logic to shut down the controls. We verified the condition by physically measuring the signal (mA) at the input at the card.

- There are multiple possibilities for cause of this type of error. It could possibly be a cable short issue, electrical swivel issue in the cable reel, a pinched length cable as the signal has to make it all the way from the boom nose to the cabin along the boom, a moisture issue in one of the connectors and junction boxes or a defect of the boom-head angle sensor.

- During testing we also notice that the failure varied at different boom angles.

- In order to identify the cause of this failure, we connected our sensor simulator (4mA to 20mA / allowable range) to different entry points on the boom, starting at the boom nose, continuing at the overall length cable reel and the boom base connector close to the boom pivot pin.

- We had the same failure when connecting the simulator to the boom nose, thereby ruling out a defective boom head angle sensor.

- We had the same failure when connecting to the cable reel, thereby eliminating a pinched length cable or defective or dirty electrical swivel in the cable reel as the problem.

- We had no failure when connecting to the outgoing connector at the boom base close to the pivot pin (cable connection from boom base to the main crane electric box X2). Thus, we knew the problem was located in the cable from the cable reel to base boom base or the connector thereof.

- We opened the connector and condensation water flowed out of the Cannon connector and water dripping out of the cable that had several kinks and damaged insulation in several areas. Contacts were badly corroded and mud was found between the 26 pins of the connector. Obviously with higher boom angle, the water moved right over all the pins causing the lower resistance and therefore higher amperage.

- The connector was cleaned out and dried temporarily and the cable repaired temporarily with fluid insulation tape until the BTS Parts Team could order a new cable assembly with connector.

- The crane was tested and worked out satisfactorily with the temporary fix.

- While working on this intermittent issue, we identified that some of the speed control potentiometers in the armrest were defective. This caused a failure indication S0146, S015A and S0164 on the PDC screen. We instructed the local technician how to replace those new potentiometers in the armrest after our parts team supplied new ones.

- We also noticed that the LCD of the PDC screen faded out over time and with increasing temperature; black lines and spots actually developed on the LCD over our time there. This is a sign of age that will ultimately lead to the LCD to becoming unreadable. The original PDC LCDs are obsolete however the BTS Parts Team can easily provide an LCD replacement kits when the time is right.

- When we left site, the crane was operational, and the local crew had a number of smaller maintenance tasks to complete. Our customer was very happy to have a fully functional and reliable crane back on their jobs.

BTS was the successful provider of crane electronic repair on this Demag AC300 PAT Hirschmann PDC LMI as well as numerous other crane electronic repair service for machines all over the United States and the world. If you need assistance with your Demag crane, please dont hesitate to contact us. We are available to support you via phone consultation or on-site if needed. You can reach us toll free in the US at 855.BODE.TEC or worldwide at +1.303.433.8878