With the evolution of industrial development across the globe, overhead crane systems booked notable place in different applications ranging from high-rise building construction to road and bridge construction. The system is basically used to move heavy materials easily and safely at construction sites. In such conditions, the system always demands to be modernized in different ways: from crane safety device to new operation tools.

As your business grows with the induction of new technology and innovation and so do your way to handle the entire works, you should make it your priority to upgrade the system frequently. With the advent of high-end technology, the engineers are introducing highly advanced and more sensitive devices like LSI wireless GS550 display to make sure the system is well-equipped with essential devices to deal with the challenges.

In this blog, we will discuss why it is necessary for a crane operator to upgrade his crane systems, and we will also talk about the modern-day technology that turns the system more efficient and productive.

Increased requirement to move the load asks for more capacity, smarter control, automation and quicker operating accuracy. The existing crane system may not be advisable for removing loads after a fixed timeline because of either increased requirements or fading parts. Moreover, outmoded system can also disfigure your profits through increased production cost.

Structural upgrade turns the system cost-effective:

The modern-day structural elements are made to bear the mechanical forces in excess of those experienced in everyday operations. Since the structural life of a crane system extends upto 30 years, the extent of load capacity gets reduced over the period. And it starts increasing the cost per assignment. In such cases, structural upgrade is required to retain the cost-efficiency of a crane system.

Mechanical upgrade improves the life of crane:

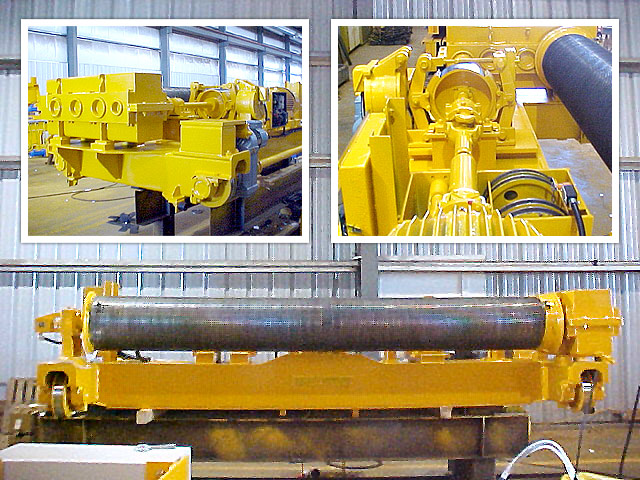

Mechanical parts in a crane system are believed to be vital elements that enable the system to work for a long span of time. Some important parts like wheels, gears, load moment indicator, bearings, etc. are made to function for upto 20 years. Technical advancement in crane systems has made it possible for the manufacturers and engineers to infuse more life-like elements to work with the utmost accuracy.

One of the most significant innovations in crane system is to replace or to repair the parts periodically. It makes sure the system is highly reliable and productive.