Project Description

The BTS Tech™ team of crane repair technicians take great pride in being some of the world’s most knowledgeable and effective crane repair technicians. With over 35 years of crane industry experience we provide expert crane repair, refurbishment, calibration, and parts services for the crane rental, rigging, construction, and refinery industries. Contact us toll free in the US at 855.BODE.TEC or internationally at +1.303.433.8878

Demag AC665 PAT PDC LMI Repair

We were able to help one of our customers in Africa with their Demag AC665 PAT PDC LMI Repair. The job included a thorough evaluation of the PAT-Hirschmann PDC LMI system as well as the pinning system inside the boom. We appreciate the hospitality of our hosts in Africa and look forward to returning.

- We assisted our customer during removal and re-installation of the two telescope cylinders for rework purpose.

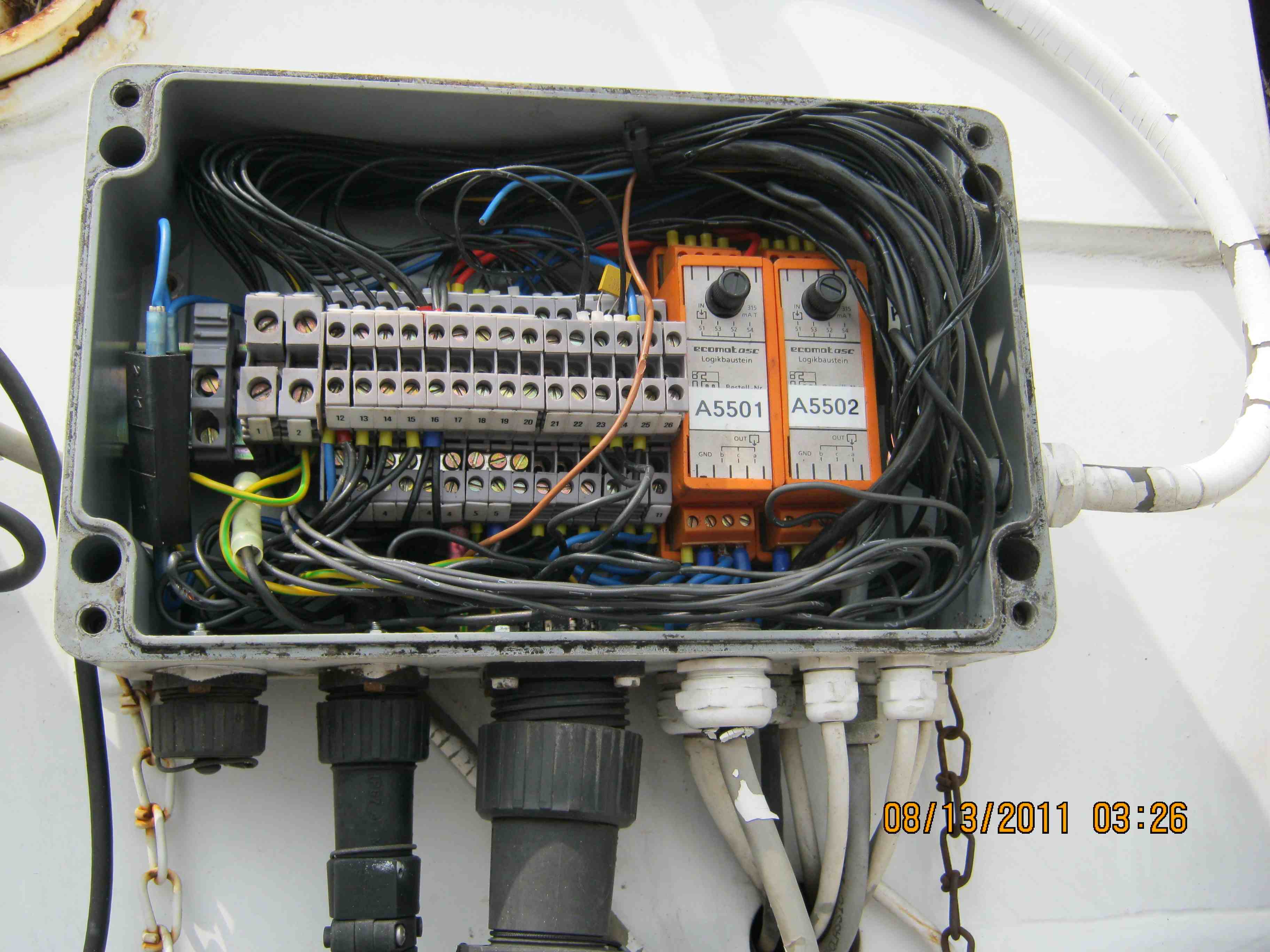

- While the cylinders and SVE unit where removed out of the boom we inspected and repaired all boom internal electric parts and electro-mechanic parts, such as proximity switches, target plates, junction boxes and wiring.

- Upon boom reassembly, the external pumps for the boom pinning system were tested. We found several hydraulic valve failures and repaired or replaced them. During testing we had to replace 3 pump motors due to defect, mainly due to water and moisture ingress. We found various wiring issues, short circuits, broken wires or brittle insulation – replaced most of the pinning pump wiring.

- We checked all boom pinning and boom locking accumulators for the right charge with nitrogen and found all low, some had to be replaced and charged, some recharged.

- We tested the boom locking and boom pinning safety electronic on the telescope section and found various malfunctions due to defective electronic module, defective relays or wiring issues.

- During electrical testing we found the electrical swivel defective and shorting while swinging the turntable causing to switch off major fuse breakers. Also the failure caused problems for the outrigger pressure indication and the carrier operation. We removed the existing electrical swivel and installed new electrical swivel.

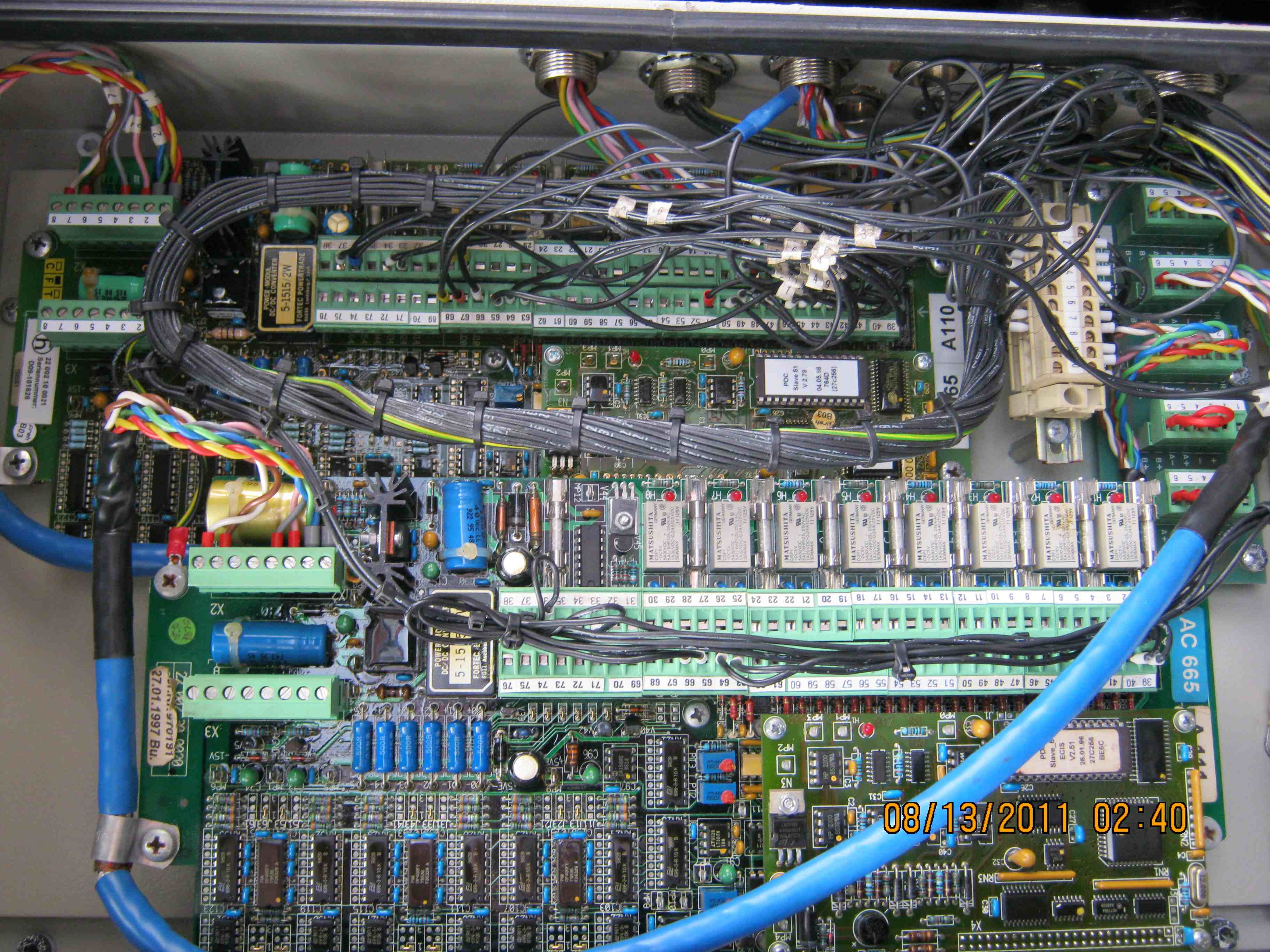

- All external sensors were checked and adjusted. All analog and digital input signals, such as proximity switches, were checked at the PDC multisensor cards and failure were repaired.

- One control lever (Joystick) had to be replaced due to unstable output signal.

- Several hydraulic valves in the boom hoist circuit and swing circuit had to be cleaned out and repaired.

- We repaired several PDC control system issues and tested the complete PDC crane control logic.

- Part of our final testing was to ensure that all crane telescope percentage options are functioning correctly in automatic mode and that SVE locking and boom pinning is functioning safe and correctly. Intensive boom testing was performed without and with load suspended.

- The LMI was tested and cut-off tests performed with all boom functions.

If you have a similar issue feel free to call our service department for a free consultation toll free in the US at 855.BODE.TEC or internationally at +1.303.433.8878